#include <Arduino.h>

#include <SimpleFOC.h>

#include <SimpleFOCDrivers.h>

#include <Wire.h>

#include <settings/stm32/STM32FlashSettingsStorage.h>

#include <encoders/ma730/MagneticSensorMA730SSI.h>

#include <encoders/ma730/MagneticSensorMA730.h>

#include <encoders/hysteresis/HysteresisSensor.h>

#include <comms/telemetry/SimpleTelemetry.h>

#include <comms/telemetry/TeleplotTelemetry.h>

#include <utilities/stm32math/STM32G4CORDICTrigFunctions.h>

#define SERIAL_SPEED 115200

#define MUX_SELECT PA6

#define BUTTON PB5

#define BATT_VOLTAGE_SENSE PA4

#define TEMP_SENSE PA5

#define LED PC6

// Define CAN bus pins

#define CAN_TX_PIN PB9

#define CAN_RX_PIN PB8

// BLDC motor & driver instance

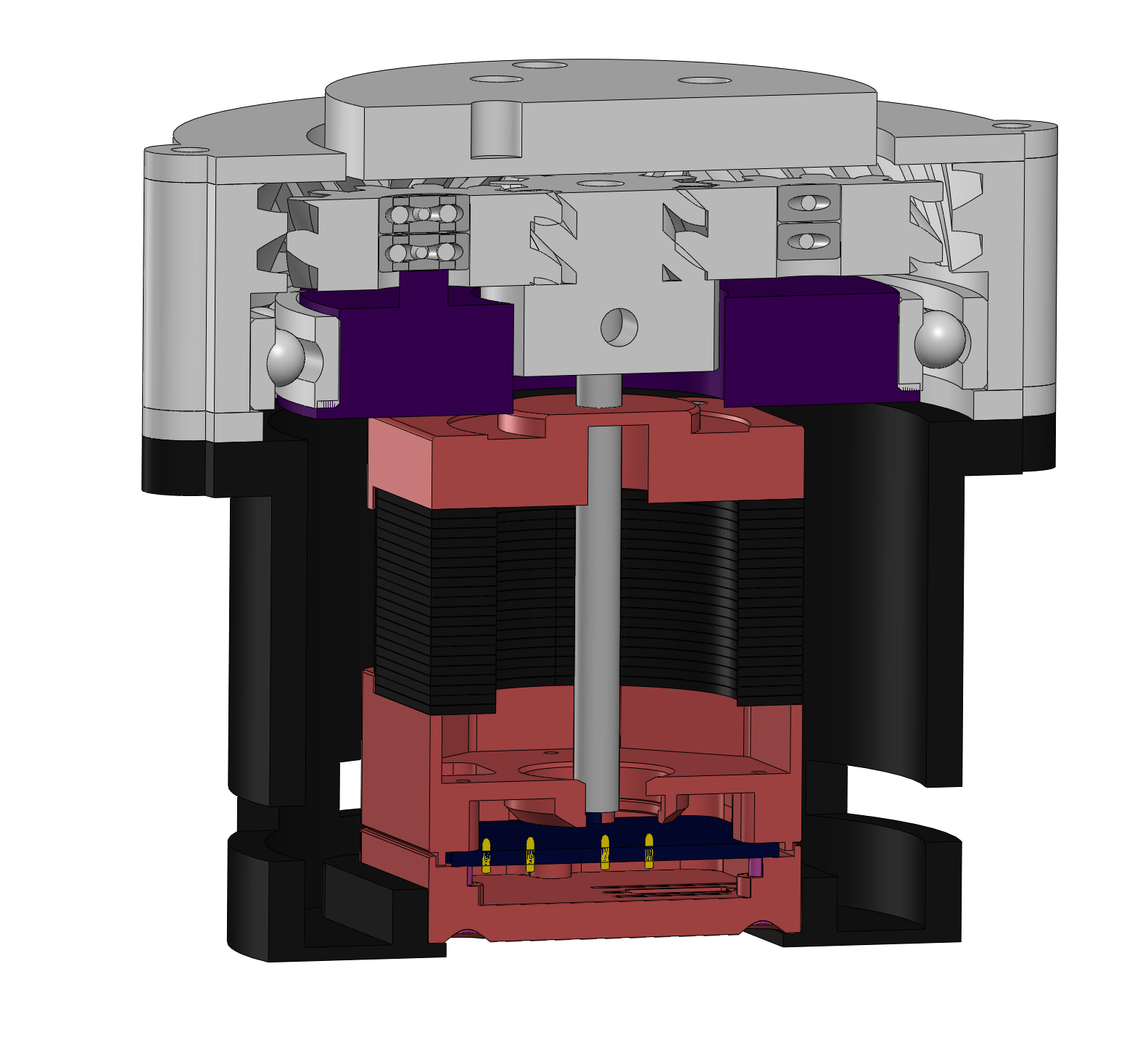

BLDCMotor motor = BLDCMotor(5, 5.2f, 120.0f, 0.000831f); // int pp, float R = NOT_SET, float KV = NOT_SET, float L = NOT_SET

BLDCDriver3PWM driver = BLDCDriver3PWM(PA0, PA1, PA2);

//Position Sensor

MagneticSensorMA730 sensor = MagneticSensorMA730(PB12);

HysteresisSensor hysteresisSensor = HysteresisSensor(sensor, 0.001f);

LowsideCurrentSense current_sense = LowsideCurrentSense(0.003, 46, PB0, PB1, PA3);

// settings

STM32FlashSettingsStorage settings = STM32FlashSettingsStorage(); // use 1 page at top of flash

// instantiate the commander

Commander command = Commander(Serial);

void doMotor(char* cmd) { command.motor(&motor, cmd); };

void doSave(char* cmd) { settings.saveSettings(); };

void doLoad(char* cmd) { settings.loadSettings(); };

void doReinit(char* cmd) { motor.sensor_direction = Direction::UNKNOWN; motor.zero_electric_angle = NOT_SET; motor.initFOC(); };

void doHysteresis(char* cmd) { hysteresisSensor._amount = atof(cmd); Serial.print("Hysteresis: "); Serial.println(hysteresisSensor._amount, 4); };

void doSetSensor(char* cmd) {

if (cmd[0]=='1') {

motor.linkSensor(&hysteresisSensor);

Serial.println("Using hysteresis");

}

else {

motor.linkSensor(&sensor);

Serial.println("Using MA730");

}

};

// telemetry

TextIO textIO = TextIO(Serial);

//SimpleTelemetry telemetry = SimpleTelemetry();

TeleplotTelemetry telemetry = TeleplotTelemetry();

void doDownsample(char* cmd) { telemetry.downsample = atoi(cmd); };

void setup() {

Serial.begin(SERIAL_SPEED);

while (!Serial);

SimpleFOCDebug::enable(&Serial);

Serial.print("spin servo - firmware version ");

Serial.println(SPIN_SERVO_FIRMWARE_VERSION);

// Wire.setSCL(PB8);

// Wire.setSDA(PB9);

// Wire.begin();

// Wire.setClock(400000);

SPI.setMISO(PB14);

SPI.setMOSI(PB15);

SPI.setSCLK(PB13);

SimpleFOC_CORDIC_Config();

// driver config

// power supply voltage [V]

driver.voltage_power_supply = 10;

driver.voltage_limit = driver.voltage_power_supply*0.95f;

driver.pwm_frequency = 20000;

driver.init();

sensor.init();

hysteresisSensor.init();

FieldStrength fs = sensor.getFieldStrength();

Serial.print("Field strength: 0x");

Serial.println(fs, HEX);

// link driver

motor.linkDriver(&driver);

motor.linkSensor(&hysteresisSensor);

// current sense

current_sense.linkDriver(&driver);

current_sense.init();

motor.linkCurrentSense(¤t_sense);

// aligning voltage

motor.voltage_sensor_align = 2;

motor.current_limit = 3;

motor.voltage_limit = driver.voltage_limit / 2.0f;

motor.velocity_limit = 1000.0f; // 1000rad/s = aprox 9550rpm

// some defaults

motor.PID_velocity.P = 0.05f;

motor.PID_velocity.I = 0.05f;

motor.PID_velocity.D = 0.000f;

motor.PID_velocity.output_ramp = 1000;

motor.LPF_velocity.Tf = 0.01f;

motor.P_angle.P = 20.0f;

motor.P_angle.I = 0.0f;

motor.P_angle.D = 0.0f;

motor.P_angle.output_ramp = 1000;

motor.LPF_angle.Tf = 0.005f;

motor.torque_controller = TorqueControlType::foc_current;

motor.controller = MotionControlType::angle;

motor.motion_downsample = 10;

// load settings

settings.addMotor(&motor);

SimpleFOCRegister registers[] = { REG_SENSOR_DIRECTION, REG_ZERO_ELECTRIC_ANGLE, REG_VEL_LPF_T, REG_VEL_PID_P, REG_VEL_PID_I, REG_VEL_PID_D, REG_VEL_PID_LIM, REG_VEL_PID_RAMP, REG_ANG_LPF_T, REG_ANG_PID_P, REG_ANG_PID_I, REG_ANG_PID_D, REG_ANG_PID_LIM, REG_ANG_PID_RAMP, REG_CURQ_LPF_T, REG_CURQ_PID_P, REG_CURQ_PID_I, REG_CURQ_PID_D, REG_CURQ_PID_LIM, REG_CURQ_PID_RAMP, REG_CURD_LPF_T, REG_CURD_PID_P, REG_CURD_PID_I, REG_CURD_PID_D, REG_CURD_PID_LIM, REG_CURD_PID_RAMP, REG_VOLTAGE_LIMIT, REG_CURRENT_LIMIT, REG_VELOCITY_LIMIT, REG_MOTION_DOWNSAMPLE, REG_TORQUE_MODE, REG_CONTROL_MODE };

settings.setRegisters(registers, sizeof(registers)/sizeof(SimpleFOCRegister));

settings.settings_version = 2;

settings.init();

//settings.loadSettings();

// initialize motor

motor.init();

// align sensor and start FOC

Serial.print("Aligning...");

motor.initFOC();

// add commands

command.echo = true;

command.add('M', doMotor, "motor commands");

command.add('s', doSave, "save settings");

command.add('l', doLoad, "load settings");

command.add('d', doDownsample, "downsample telemetry");

command.add('r', doReinit, "reinit motor");

command.add('h', doHysteresis, "hysteresis amount");

command.add('S', doSetSensor, "set sensor (0=MA730, 1=hysteresis)");

// add telemetry

telemetry.addMotor(&motor);

telemetry.downsample = 0; // off by default, use register 28 to set

uint8_t telemetry_registers[] = { REG_TARGET, REG_ANGLE, REG_VELOCITY, REG_SENSOR_MECHANICAL_ANGLE, REG_ITERATIONS_SEC };

telemetry.setTelemetryRegisters(sizeof(telemetry_registers)/sizeof(SimpleFOCRegister), telemetry_registers);

telemetry.init(textIO);

Serial.println(F("Motor ready."));

Serial.println(F("Set the target using serial terminal:"));

}

void loop() {

// Motion control function

motor.move();

// main FOC algorithm function

motor.loopFOC();

// user communication

command.run();

// telemetry

telemetry.run();

}